Tata Steel UK and Swansea University announced the two have entered a three-year research collaboration to test the ability of buildings to generate, store, and release their own supply of energy.

The project leverages the concept of “active buildings,” bringing together energy generation and

energy efficiency of many varieties. Buildings account for 76% of all electricity use and 40% of all primary energy use in the U.S.

One such element of these active buildings is Tata Steel’s micro-perforated steel, which is designed for the south wall of buildings. Called a “transpired solar collector” the pre-finished steel has enhanced thermal absorption properties, which heats the air outside the building’s steel “skin.” The warmed air is pulled in through a ventilation fan and fed into the building for heating.

Image: Department of Energy Solar Energy Technologies Office

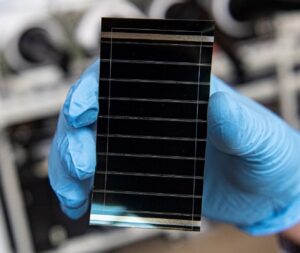

Along with micro-perforated steel, the research collaboration is exploring ways to integrate perovskite solar cells in active buildings. Perovskite solar cells are flexible, and can be printed, meaning they can be directly deposited onto coated steel.

“This technology will help us tackle the energy crisis and the climate crisis at the same time. The future is about solar energy technology being built in, not added on afterwards. These printable solar cells can be built into the fabric of our homes, shops and offices, allowing them to generate the power they need, and more. We know the concept works as we’ve demonstrated it in our Active Buildings in sunny Swansea. This new collaboration with Tata Steel will enable us to develop its potential more quickly, identifying new types of steel products that actively work to generate electricity.” Dave Worsley, head of materials science and engineering at Swansea University.

Perovskites are highly efficient, requiring less energy than traditional silicon solar cells to produce. They are lighter and cheaper than silicon cells, but degrade more rapidly, so research teams across the globe are actively looking for solutions for improving their stability.

“Getting this technology into widespread use could hardly be more timely. In the UK and elsewhere it can reduce reliance on fossil fuel energy such as imported gas. It would also ease the pressure on national electricity networks, for example by enabling us to charge up electric vehicles with surplus energy generated by our homes,” said Worsley.

“We are buoyant with the possibilities that the perovskite technology brings to the table – especially in integration to the building and construction solutions – across different value streams in Tata Steel,” said Sumitesh Das, R&D director at Tata Steel UK.

Ryan Kennedy for PV Magazine